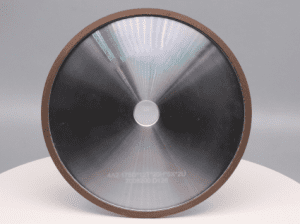

A circular saw blade diamond grinding wheel is a specialized tool used for sharpening and grinding circular saw blades. It is designed with diamond abrasive particles embedded in the wheel’s surface, which provide high cutting efficiency and durability.

Here are some key points about circular saw blade diamond grinding wheels:

Function: The primary purpose of a diamond grinding wheel for circular saw blades is to sharpen the blade’s cutting teeth and restore their original cutting performance. Over time, the cutting teeth of a circular saw blade can become dull or damaged due to use, and grinding them with a diamond wheel helps to bring back their sharpness.

Diamond Abrasive: Diamond is one of the hardest known materials and is commonly used as an abrasive in grinding applications. Diamond grinding wheels have diamond particles bonded to the wheel’s surface, which provide excellent cutting ability and long-lasting performance.

Grit Sizes: Diamond grinding wheels are available in various grit sizes, ranging from coarse to fine. Coarser grit sizes are suitable for initial grinding and removing larger amounts of material, while finer grit sizes are used for finer sharpening and polishing.

Wheel Types: There are different types of diamond grinding wheels available for circular saw blades, including straight wheels and cup wheels. Straight wheels are flat and used for sharpening the face of the blade’s teeth, while cup wheels have a cup-shaped profile and are used for grinding the side edges of the teeth.

Compatibility: When choosing a diamond grinding wheel, it is essential to ensure compatibility with your circular saw blade’s specifications. Consider factors such as the blade’s diameter, arbor size, and tooth configuration to select the right wheel that matches your blade.

Safety Precautions: It’s crucial to follow proper safety precautions when using a diamond grinding wheel. Wear appropriate protective gear, such as safety glasses and gloves, to protect yourself from any potential hazards. Follow the manufacturer’s instructions and guidelines for mounting and using the wheel correctly.

Remember, if you’re not confident in your ability to use a diamond grinding wheel properly or if your circular saw blade requires significant sharpening or repair, it’s best to seek assistance from a professional blade sharpening service. They have the expertise and specialized equipment to ensure your circular saw blade is properly sharpened and ready for use.

| Shape | Diameter

(mm) |

Layer width (mm) | Layer thickness (mm) | Inner Hole (mm) |

| 1A1W | 5/5.5/6.0/6.5 | 1.5 | 3.0 | On request |

| 4A2 | 75/100/125/150 | 5/6/10 | 2/3/5/10 | |

| 4BT9 | 75/100/125/150 | |||

| 6A2 | 75/100/125/150 | 5/6/10 | 2/3/5/10 | |

| 6A9 | 75/100/125/150 | 5/6/10 | 2/3/5/10 | |

| 12V2 | 75/100/125/150 | 5/6/10 | 2/3/5/10 | |

| 12V9 | 75/100/125/150 | 5/6/10 | 2/3/5/10 | |

| 14F1 | 75/100/125/150 | 5/6/10 | 2/3/5/10 | |

| 15V9 | 75/100/125/150 | 5/6/10 | 2/3/5/10 |